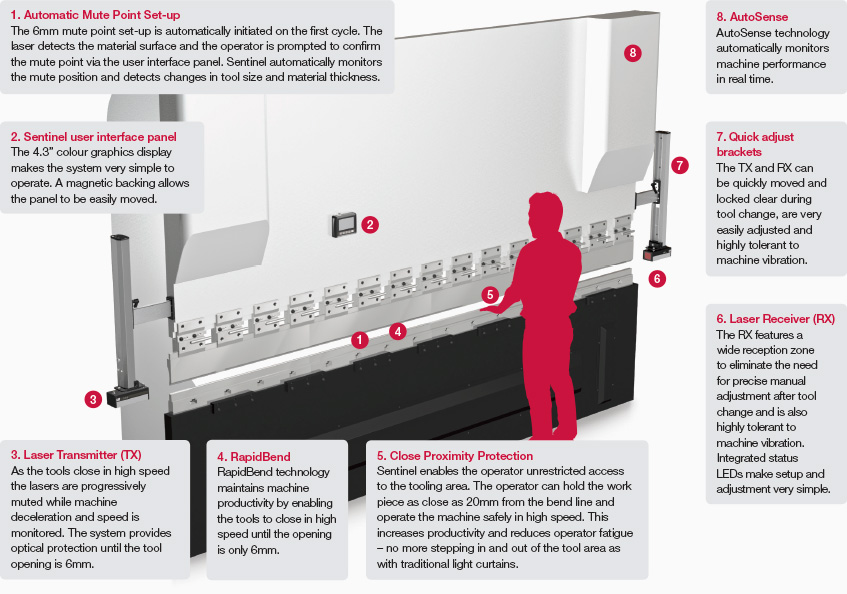

Overview

The Sentinel Plus guarding system features a laser transmitter and receiver that are mounted to the upper beam of the press brake. A continuous block laser field protects the zone around the punch tip allowing the operator to safely hold the work piece as the tools close at high-speed. If an obstruction is detected the machine is automatically stopped.

Sentinel Plus can be retrofitted to most existing press brake models and provides a complete safety solution that includes advanced optical protection, monitoring of the press brake control commands and actions, control and monitoring machine safety elements and more.

Complete optical protection

Advanced BendShield technology provides advanced optical protection by enveloping the punch tip with a protective field that has no gaps. BendShield has an object detection resolution of 2mm to detect even the smallest obstruction from any angle. Optical protection remains active until the tool opening is reduced to 2mm preventing fingers and hands entering the point of operation.

This close proximity protection allows the operator unrestricted access to the point of operation for increased productivity and unlike traditional light curtains, reduces fatigue by eliminating the need to continually move in and out of the operating area.

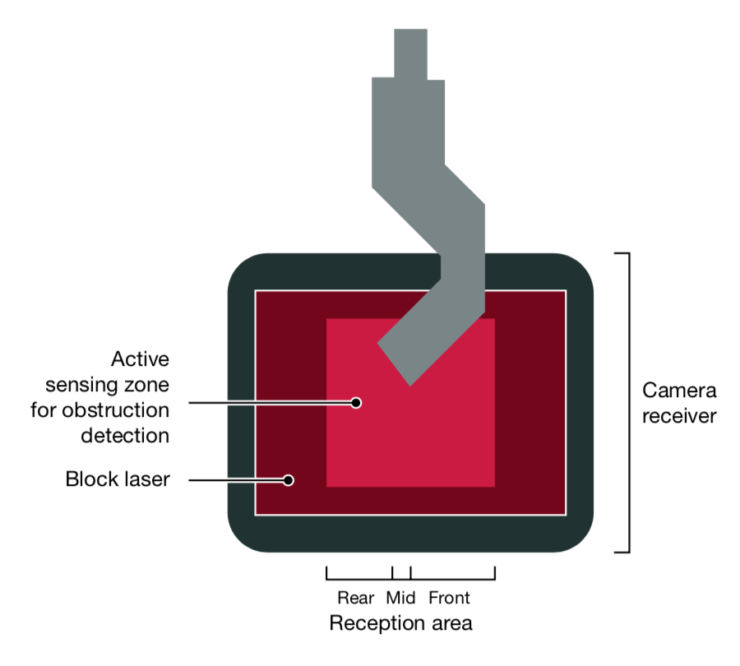

Sensor arrangement

The laser field is processed by the receiver and divided into three continuous zones to detect obstructions entering from the front, sides and rear of the tool area. The front zone provides protection forward of the tool while the middle zone protects the area just behind the tip of the punch. The rear zone provides additional protection for the open gaps created when segmented tooling is used. The protective zones are independently and automatically muted to suit different shape work pieces allowing parts to be formed safely at high speed to achieve maximum productivity.

Automatic tool alignment

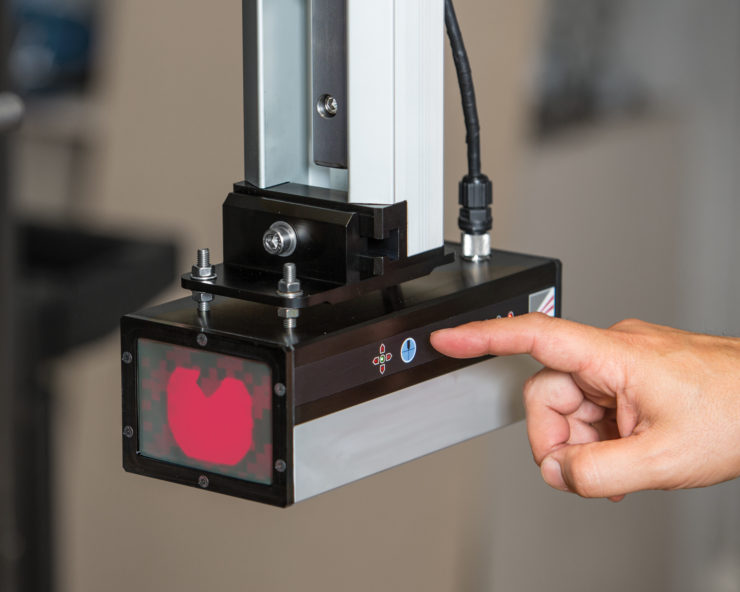

The Sentinel Plus camera receiver features automatic tool alignment that eliminates the need for precise manual adjustment and reduces tool set-up time. After tool change simply press the TOOL ALIGN button on the receiver. The receiver scans the punch to locate the tool tip, then automatically adjusts the protection zone.

Performance matters

RapidBend Plus performance technology enables your machine to operate faster and with less restrictions. RapidBend Plus works with flat sheets and box profile parts so the machine can close at high speed right down to 2mm above the material to significantly boost your productivity.

RapidBend Plus is designed for high-speed press brakes and employs a dynamic muting process that enables the tools to close safely at high-speed until the punch is just 2mm above the material surface. This minimises the slow speed travel distance on every bend cycle for both flat profile parts and box profile parts with side flanges.

RapidBend Plus is compatible with most high-speed performance CNC press brakes*, reducing the minimum speed change point down to 2mm.

*For retrofit applications, RapidBend Plus can reduce the minimum speed change point to 2mm, however results may vary depending on the press brake type and capabilities. Consult your Lazer Safe Retrofit Dealer for more information.

Advanced machine monitoring

AutoSense is an automatic monitoring technology that tracks machine operation and performance in real time. AutoSense automatically monitors control commands, motion, direction, speed and stopping performance to maintain a high level of machine and operator protection. AutoSense also guarantees compliance with international safety standards that mandate automatic monitoring of machine overrun and safe speed.

Additional monitoring

Sentinel Plus provides optional monitoring of additional machine safety elements including emergency stop buttons plus side and rear gate interlock switches with real-time status displayed on the user interface panel.

External Device Monitor (EDM)

Sentinel Plus provides the option to connect and monitor up to four external devices such as valve sensors or relays. The EDM response time is configurable and the status of each external device is displayed on the user interface panel in the event of a device failure.

Intuitive user interface

The Sentinel Plus HMI displays system and machine status in real time and provides the operator with simple to follow instructions and messages making the system very easy to operate. The active status of the optical protection is clearly displayed and the operator can quickly change guarding modes with the press of a button.

The panel features a magnetic backing allowing it to be moved and placed on the front of the machine within easy reach and view of the operator.

Mounting brackets

Sentinel Plus systems are supplied as standard with a free-sliding linear mounting bracket system that attaches the transmitter and receiver to the upper beam of the press brake.

The brackets are manufactured from an extruded high-tensile alloy for rigidity and resistance to machine vibration with linear rails and bearings providing precision vertical adjustment of the transmitter and receiver. During tool change, the transmitter and receiver are locked clear allowing tools to be easily removed and loaded from the ends of the machine.

After tool change, the transmitter and receiver are quickly moved back into position. The receiver status LEDs provide clear indication when the system is aligned so the tool change process is very simple and takes only a matter of seconds.

Specifications

| SENTINEL PLUS | SENTINEL PLUS AUTOMATIC | SENTINEL PLUS XL | |

|---|---|---|---|

| Controller | |||

| Hardware | TUV CE Certified SIL 3 safety controller with encoder feedback system | ||

| Software | TUV CE Certified kernel software with application software interface | ||

| Technology | RapidBend Plus / AutoSense / BendShield | AutoSense | |

| Laser transmitter / receiver | |||

| Laser transmitter (TX) | CLASS 1 block laser | ||

| Receiver (RX) | Camera receiver | ||

| Maximum recommended optical range | 8 metres / 26 feet (6 metres / 20 feet when using Automatic Brackets) | 15 metres / 50 feet | |

| Minimum object detection resolution | 2mm | 9mm | |

| Minimum speed change point | 2mm | 14mm | |

| Connector type | M12 12 pin | ||

| Tool compatibility | V tools and non-standard tools | ||

| Special functions | Automatic Tool Alignment / Special Tools Mode | Automatic tool confirmation | |

| Integrated status LEDs | TX status (power / laser) RX status (power / sensors / automatic alignment) | TX status (power / laser) RX status (power / sensors / alignment confirmation) | |

| User interface panel | |||

| Display | 4.3″ widescreen colour graphics display | ||

| Connector type | M12 8 pin | ||

| Mounting brackets | |||

| Standard linear brackets | Available in 520mm / 700mm / 1000mm lengths | – | Available in 700mm / 1000mm lengths |

| Automatic brackets | – | Available in 700mm length | – |